Simulation Results

pH and Voltage Response Over Time

The graph shows the decrease in pH over time, starting at 7 (neutral) and moving towards acidic levels as food spoils, along with the corresponding voltage response.

3D pH Distribution and Voltage Maps

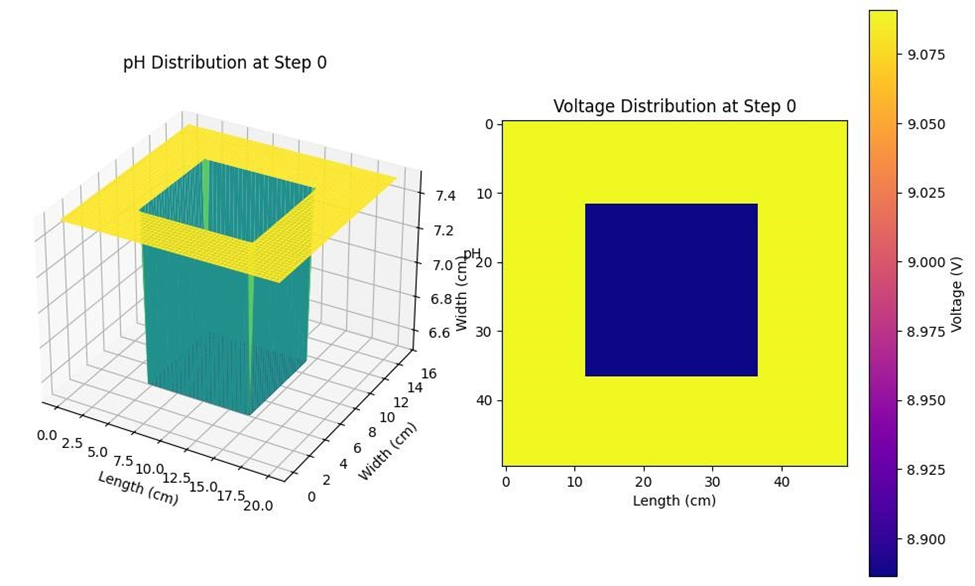

Initial State (Step 0)

Initial uniform pH distribution (around 7.4) across the container, with consistent voltage readings indicating fresh conditions.

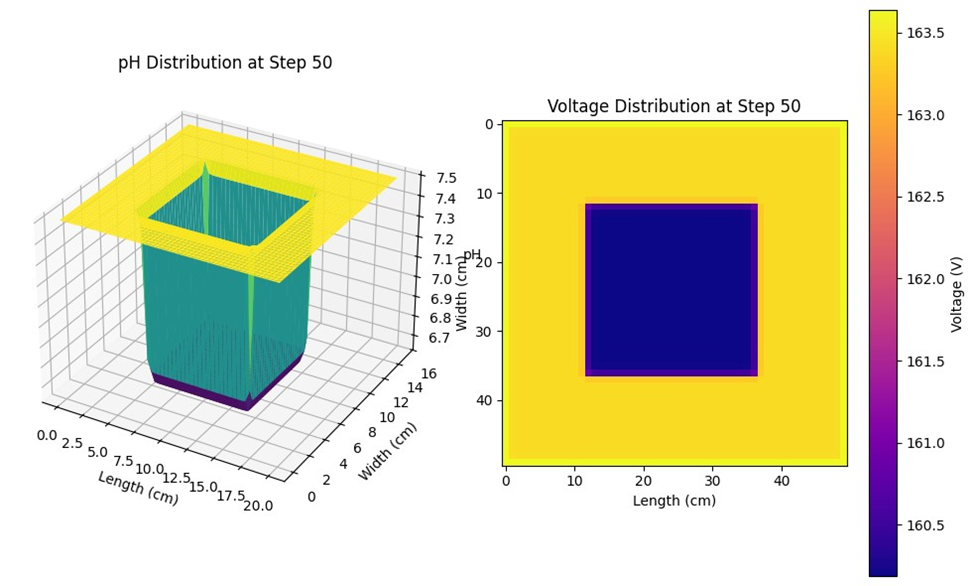

Early Progress (Step 50)

Gradual pH changes begin to appear, with early signs of spoilage detected in localized regions.

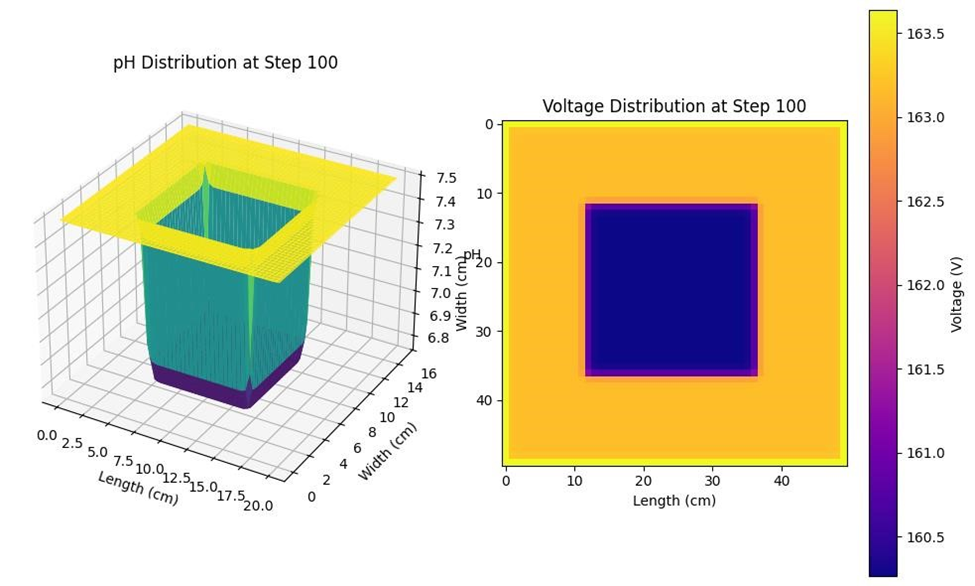

Advanced Stage (Step 100)

The 3D pH plot indicates continued spoilage with more areas showing lower pH values. The voltage distribution shows a further decline in signal, with larger areas categorized as "Spoiled."

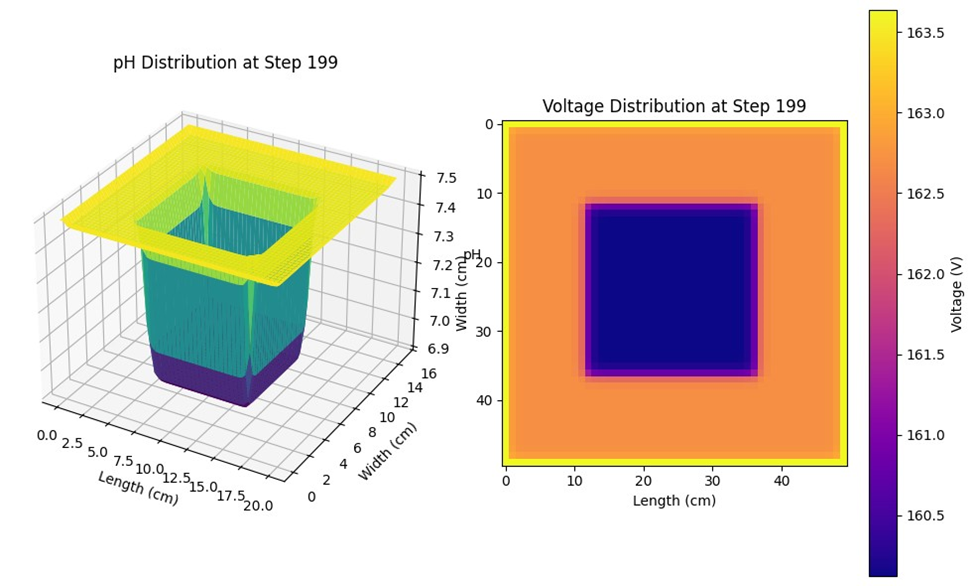

Final State (Step 199)

By this step, spoilage has significantly progressed, with most areas showing low pH values in the 3D plot. The voltage map reflects widespread spoilage, with nearly the entire container falling below the "Caution" threshold.